C35E.pdf

C35R.pdf

C40E.pdf

C40R.pdf

*C45E.pdf

C45R.pdf

25CRMO4.pdf

25CRMOS4.pdf

42CRMOS4.pdf

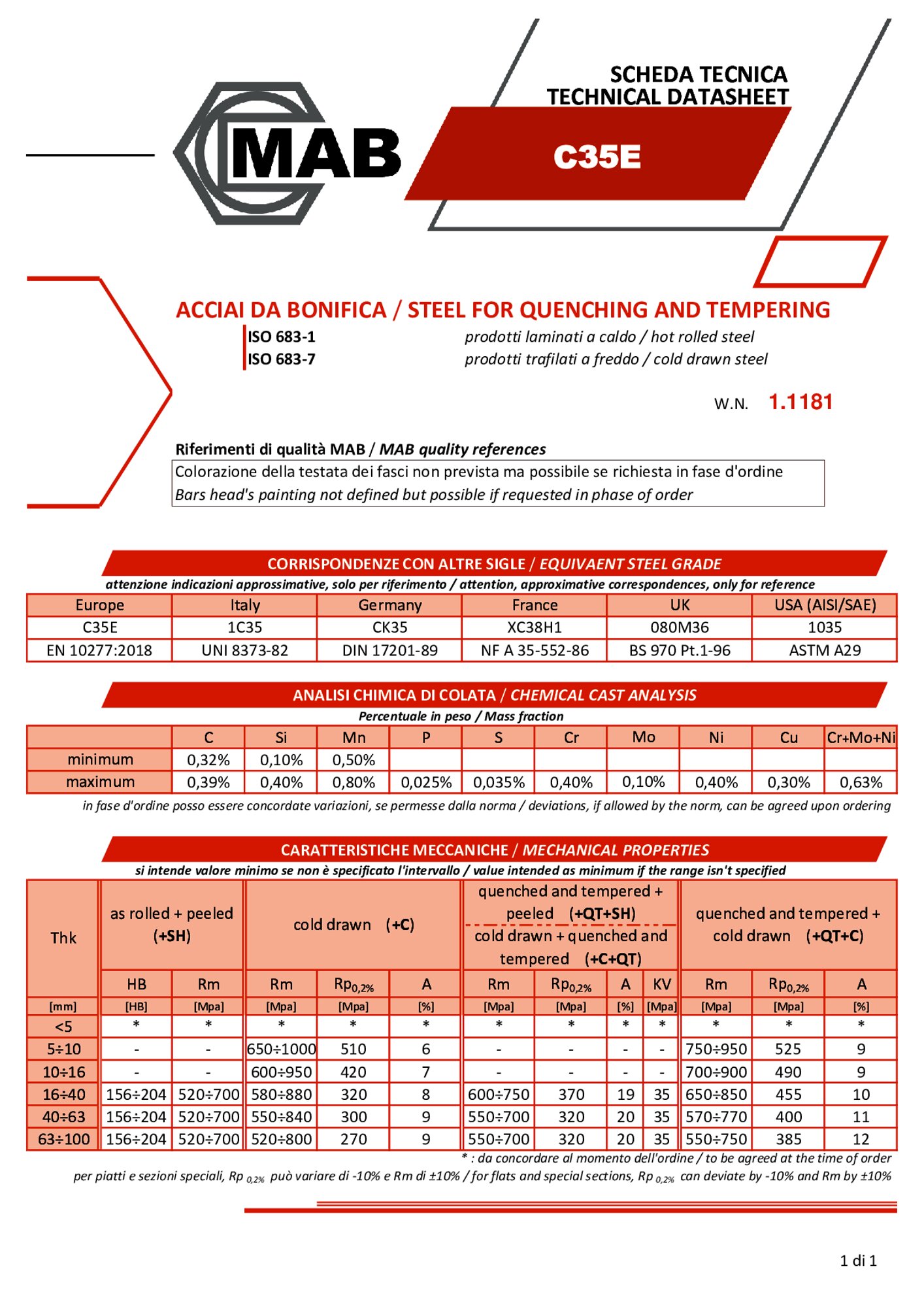

Steels for quenching and tempering are divided into: non-alloy steels and alloy steels; they have the best compromise between mechanical strength and toughness. They are mainly used for mechanical components, for which good impact and vibration resistance properties are required (for example, connecting rods, pins, shafts, levers, etc.).

We could say that the percentage of carbon varies between 0.21% and 0.60%.

There are many steel grades available on the market with only carbon content (eg. C45E-R) or with alloy elements in variable percentage (Ni, Cr, Mo, Mn);

Alloy elements have the following functions:

These steels are usually tempered in water or oil at about 620 °C.

Examples of non-alloy steels for quenching and tempering: C35E, C35R, C40E, C40R, C45E, C45R

Examples of alloy steels for quenching and tempering: 42CrMo4, 25CrMoS4

Hot rolled material is purchased according to EN ISO 683-3 whereas cold drawn material is sold according to EN 10277: 2018